In the quirky world of 3D printing, where creativity meets technology, ironing is the secret sauce that takes prints from drab to fab. Imagine transforming a rough, bumpy surface into a smooth masterpiece—like giving your favorite shirt a fresh press, but for your plastic creations. It’s not just a fancy term; it’s a game-changer for anyone looking to elevate their 3D prints.

Table of Contents

ToggleWhat Is Ironing In 3D Printing

Ironing in 3D printing refers to a process that smooths out the outer layers of a print, resulting in a more refined and professional finish. This technique enhances the aesthetics and usability of 3D objects, transforming prints into polished masterpieces.

Definition and Overview

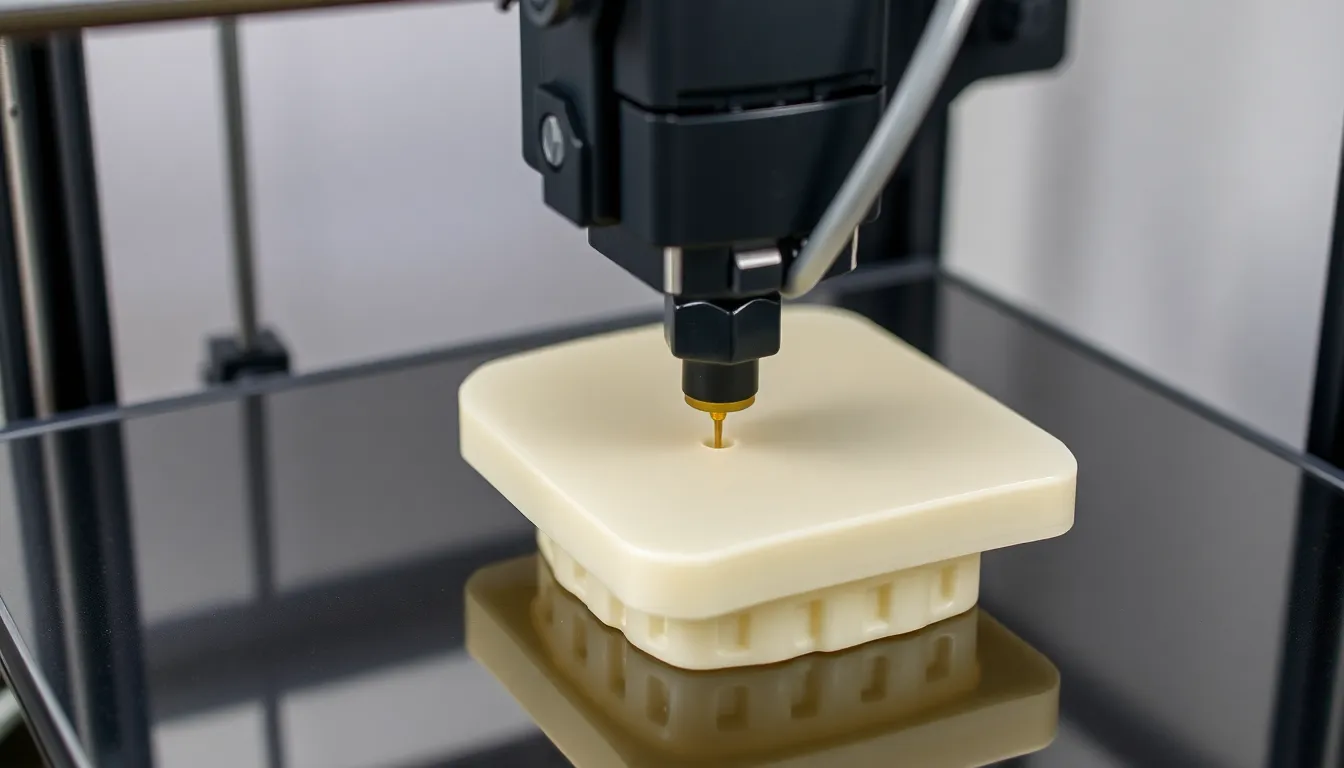

Ironing involves the printer extruding a thin layer of material over previously laid layers. The nozzle moves back and forth across the surface, heating the filament just enough to flatten uneven areas. This method minimizes visible layer lines, creating a smoother finish. Ironing is commonly used in Fused Deposition Modeling (FDM) printers. By applying this technique, users can achieve better surface quality, enhancing the overall appearance of 3D printed models.

The Purpose of Ironing

The main purpose of ironing is to improve the surface quality of 3D prints. This process helps eliminate imperfections and creates a visually appealing finish. Ironing can reduce the time spent on post-processing, such as sanding or painting. It significantly enhances the aesthetic value of prototypes and functional parts, making them more presentable. Moreover, this method can contribute to better adhesive properties in certain applications, allowing for improved layer bonding in the final product.

How Ironing Works

Ironing in 3D printing primarily focuses on refining print surfaces. This technique results in smoother finishes, improving both aesthetics and functionality.

The Ironing Process

The ironing process begins with the printer applying a thin layer of filament over existing layers. During this step, the nozzle moves back and forth, applying heat just enough to flatten uneven areas. Flat surfaces emerge as the ink melts slightly, reducing visible layer lines that detract from quality. The temperature choice is crucial, as excessive heat can cause deformation, while insufficient heat won’t yield the desired effect. By strategically enhancing outer layers, the result is a polished appearance that elevates the overall model.

Software Implementations

Software configurations play a vital role in effective ironing. Most slicing software features an ironing option to enable this process. Users often adjust parameters like nozzle height and speed to customize the ironing effect. Specific slicers, such as PrusaSlicer and Cura, provide intuitive settings that allow users to experiment with different ironing techniques. With these tools, fine-tuning process settings results in optimal outcomes, enhancing the reliability and aesthetic appeal of 3D prints.

Benefits of Ironing in 3D Printing

Ironing in 3D printing offers significant advantages, especially in improving print quality and efficiency.

Improved Surface Finish

Enhanced surface finish results from effective ironing. The technique smooths out imperfections, which increases visual appeal. Printing layers appear more uniform, enhancing the overall aesthetic. This refinement not only boosts attractiveness but also elevates the professionalism of the final product. Applying heat judiciously during ironing allows the filament to merge seamlessly, minimizing noticeable layer lines. Users often find that models with better surface finishes receive positive feedback during presentations or showcases. Improved surfaces also mean less likelihood of paint or finish application issues, ensuring a superior end result.

Reduced Post-Processing

Reduced post-processing becomes evident with the ironing technique. Many users experience less need for additional sanding or surface treatment. Ironing effectively lowers the amount of labor involved in preparing prints for final presentation. Since it leaves prints smoother, operators often skip multiple steps in their workflow, enhancing productivity. Time spent on manual post-processing diminishes significantly, allowing for quicker project turnarounds. This efficiency in production not only saves time but also reduces costs associated with materials and labor.

Limitations and Considerations

Ironing in 3D printing has its limitations and factors to consider for effective implementation.

Material Constraints

Material selection plays a crucial role in the ironing process. Not all filaments respond well to ironing techniques. For instance, certain thermoplastics like PLA and PETG yield better results due to their heat sensitivity. Using materials that don’t adhere well or shrink dramatically under heat can negatively affect the final finish. Users must carefully evaluate filament characteristics, as some materials may warp or deform when heated during the ironing stage. Additionally, color properties and textures within filaments can influence how effective ironing is in achieving the desired smoothness and appearance.

Print Speed Implications

Print speed significantly impacts the effectiveness of ironing. Slower speeds often yield smoother finishes, as the nozzle has more time to evenly distribute heat. Quick print settings can lead to insufficient melting of the outer layers, leaving visible imperfections. User adjustments for speed settings influence how well the process flattens layers without introducing new anomalies. Additionally, finding the right balance between speed and quality is essential for maintaining overall print efficiency. Experimenting with different speeds can optimize results and enhance the ironing outcome.

Ironing in 3D printing represents a significant advancement in achieving high-quality finishes. By smoothing out surface imperfections it elevates the overall aesthetics and functionality of printed models. This technique not only enhances the visual appeal but also streamlines the post-processing phase, saving both time and materials.

With careful temperature control and the right settings in slicing software users can unlock the full potential of their prints. While material selection and print speed are important factors to consider the benefits of ironing make it a valuable tool for anyone looking to improve their 3D printing outcomes. Embracing this technique can lead to more polished results and greater satisfaction in the final products.